Mirror Mounts

Mirror mounts provide a means to adjust the angle of a mirror on two axis: the pitch axis (up and down) and the yaw axis (side to side). They are available in many sizes to hold mirrors ranging in diameter from 12.7 to 300mm. The most widely used, cost-effective, and stable of the mirror mounts is the kinematic type. Its design is fairly simple providing constraints in each of the six degrees of freedom just once, ensuring excellent stability in temperature varying environments. Gimbal mounts are another type commonly used mount which provides an exceptionally angular adjustment range as well as the ability to minimize adjustment cross talk. Mirror mounts are used in almost all optical applications primarily for beam routing, or in other words, getting the optical beam of light from the source to the point of interest. Industries that utilize these mounts include research, bio-medical, life sciences, astronomy, metrology, semiconductor, and more. If one of our many catalog mirror mounts does not meet your requirements, just send us a request for a custom version.

-

Standard-Grade Kinematic Mirror Mounts

-

Performance-Grade Kinematic Mirror Mounts

-

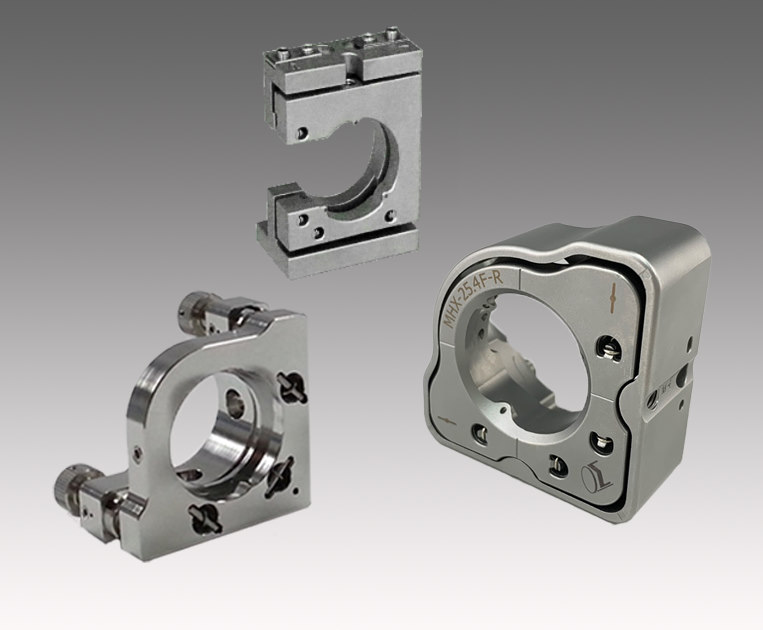

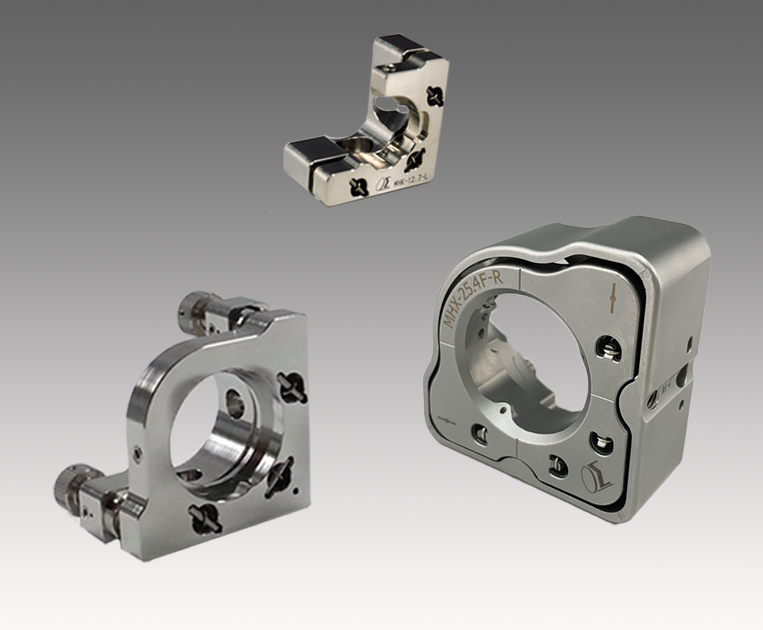

Precision-Grade Stainless Steel Mirror Mounts

-

Top-Adjust Mirror Mounts

-

Stainless Steel Piezomotor Mirror Mounts

-

Frameless Mirror Mounts

-

Vacuum Compatible Mirror Mounts

-

Large Diameter Mirror Mounts

-

True Gimbal Mirror Mounts

-

Adapters for Mirror Mounts

Selection Guide for Kinematic Mirror Mounts

Groups |

Description |

Mirror Diameters (mm) |

Features |

Mount Families |

|---|---|---|---|---|

Standard-Grade Mounts |

Standard-Grade mirror mounts provide solid performance at a cost-effective price. They are designed for use in an optics lab but are also suitable for integration into complex optical systems. |

Φ12.7 (0.5") |

|

|

Performance-Grade Mounts |

Performance-Grade mirror mounts provide additional features and enhanced stability over standard grade mounts. They are best suited for laser processing or interferometer applications but also ideal for use in an optics lab. |

Φ12.7 (0.5") |

|

|

Precision-Grade Mounts |

Precision-Grade Mounts are made exclusively from stainless steel and provide the highest level of performance and stability. Complimenting their high performance is a host of additional useful features and options. |

Φ12.7 (0.5") |

|

*The indicated millimeter-to-inch diameter conversion values are rounded

Selection Guide for Speciality Mirror Mounts

Groups |

Description |

Mirror Diameters (mm) |

Features |

Mount Families |

|---|---|---|---|---|

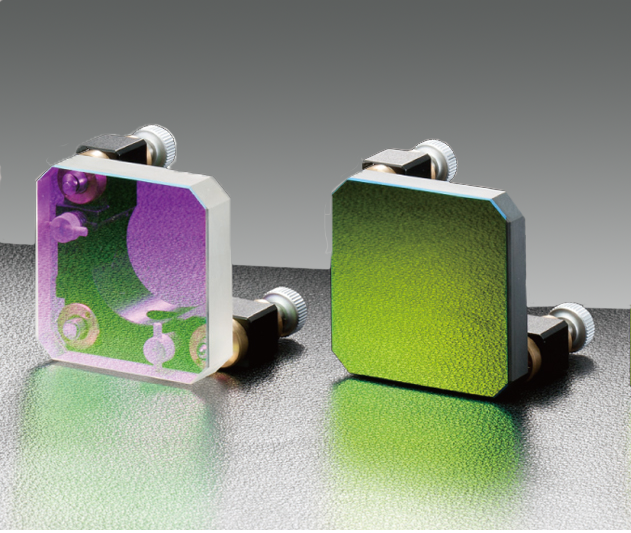

Top-Adjust Mounts |

Top Adjust mirror mounts have vertically oriented adjustments located safely and conveniently above the mirror so your hands are never in the beam path. This configuration enables thinner profiles for use with beam splitters and in compact spaces. |

Φ10.0 (0.4")* |

|

|

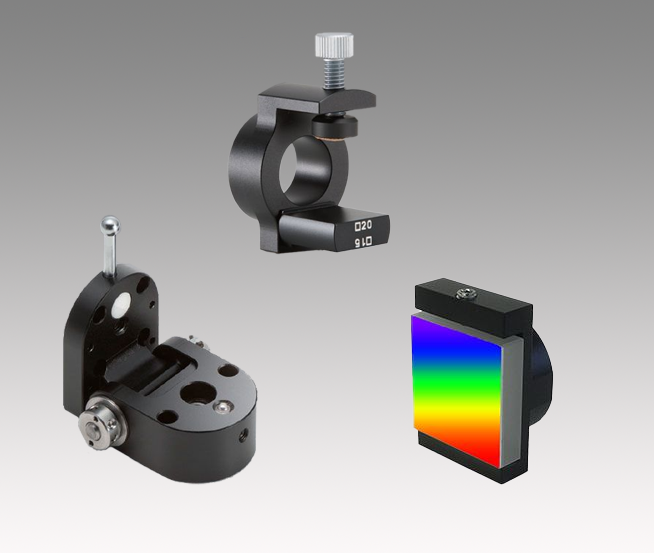

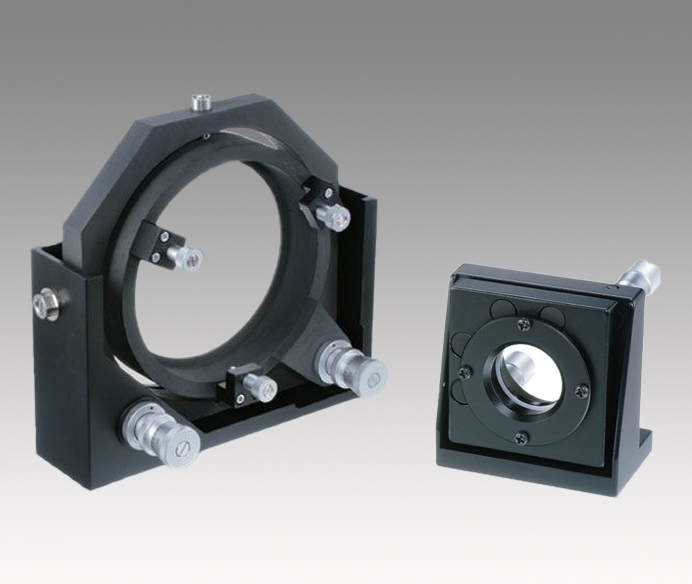

True Gimbal Mounts |

Gimbal mounts have axes of rotation (pitch and yaw) which intersect at the center of the surface plane of the optic so that the beam length will not change during adjustment. True gimbal mounts always have rotation axes that are true (parallel and orthogonal) to the mounting surface. This configuration eliminates cross talk between the adjustments. |

Φ20.0 (0.8")* |

|

|

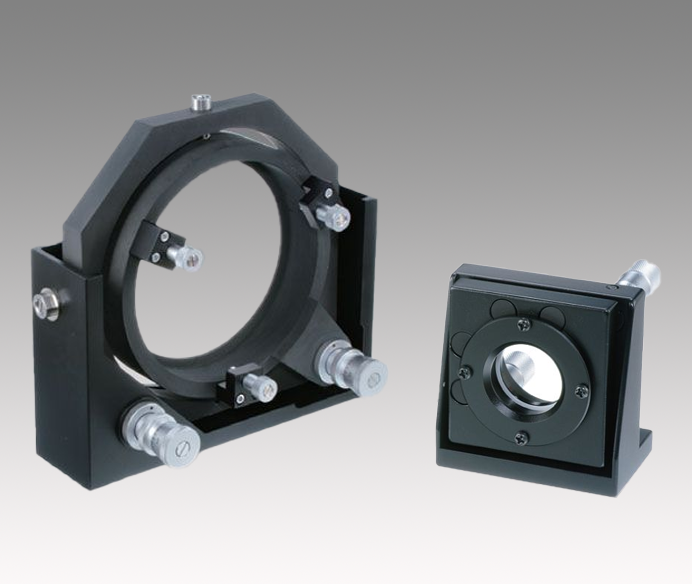

Large Diameter Mounts |

Large diameter mounts are made to position and align mirrors with diameters from 80 to 300 mm. In addition to their diameter capacity, they have exceptional adjustment sensitivity and do not exhibit any adjustment cross-talk during alignment. |

Φ80.0 (3.2")* |

|

|

Vacuum Compatible Mounts |

Vacuum Compatible mounts are made from stainless steel and processed with special lubrication and vacuum-level cleaning. These mounts have less volatile organic compounds to ensure minimal outgassing in a 10E-6 Torr vacuum environment. |

Φ12.7 (0.5") |

|

|

*The indicated millimeter-to-inch diameter conversion values are rounded