Aspherical Lenses

Aspheric lenses are formed using either CNC machining or molding using glass or plastic as the substrate. These lenses have surface profiles such as hyperboloid, paraboloid, acylinder or other higher order surface profiles. Aspheres are typically used to correct spherical aberration or to simplify the number of elements in a design or both. We also manufacture custom solutions in case one of our many standard lenses do not meet your requirements.

Advantages of Aspherical Lens Systems

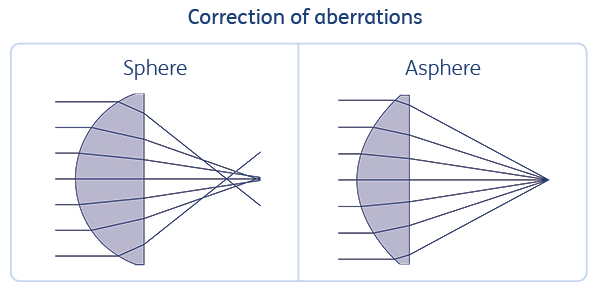

ELIMINATION OF ABERRATIONS

With spherical imagining lenses, its single-radius profile leads to blurred, out-of-focus images because all of the light rays cannot meet at the focal point. This is known as aberration. Aspheric optics have one or more multi-radiused (aspherical) surfaces that deviate from the shape of a simple sphere. This complex profile allows the light rays to converge at one point and the spherical aberrations to be eliminated. Thanks to modern production technologies, we are able to manufacture aspheric lenses with highest precision even in series.

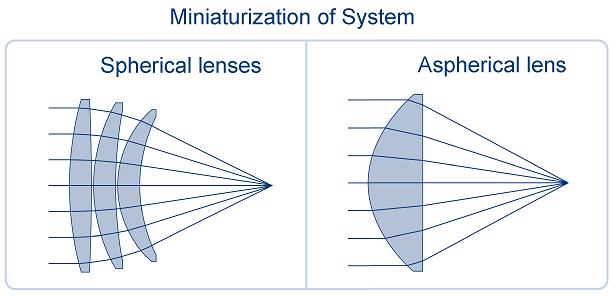

SMALLER, LIGHTER OPTICAL SYSTEMS

The use of aspheric lenses allows an optical system to be made both smaller and lighter. An application that requires several spherical lenses can sometimes be replaced by one aspheric lens. This is made possible because the lenses that would have to be used to correct spherical aberration can be eliminated so the entire system becomes more compact and the overall weight can be reduced. An illustrative example of the reduction of an optical system can be found in beam expansion. The monolithic beam expander consists of a single aspheric lens per element. Due to the afocal design, individual monolith beam expanders can be connected in series. This allows a high variance in the range of beam expansion. Compared with conventional Kepler and Galilean telescopes, the overall length is reduced by up to 50% while maintaining the same quality and magnification.