EXC™ Precision-Bearing Steel Stages

Our vertical travel EXC™ Precision-Bearing Steel Stages feature Opto Sigma's patented EXC™ precision bearing ways, providing the highest performance stages in our lineup. These bearing ways are not separate parts, as with competing stages, but processed directly into the body and base of the stage resulting in the highest stiffness, straightness and smoothness of any stage on the market. This bearing design means that there is nothing to come loose or un screwed, so it's impossible to lose your preload. OptoSigma's bearing technology also gives our stages other advantages like high load capacity and lowest profile vs. any stage on the market. They remain unmatched in overall performance to this day. All EXC™ stages are made entirely from hardened tool steel and are plated with an RoHS-Compliant black chrome. If one of our many catalog stages does not meet your requirements, send us a request for a custom stage. OptoSigma is, after all, the industry leader in translation stages.

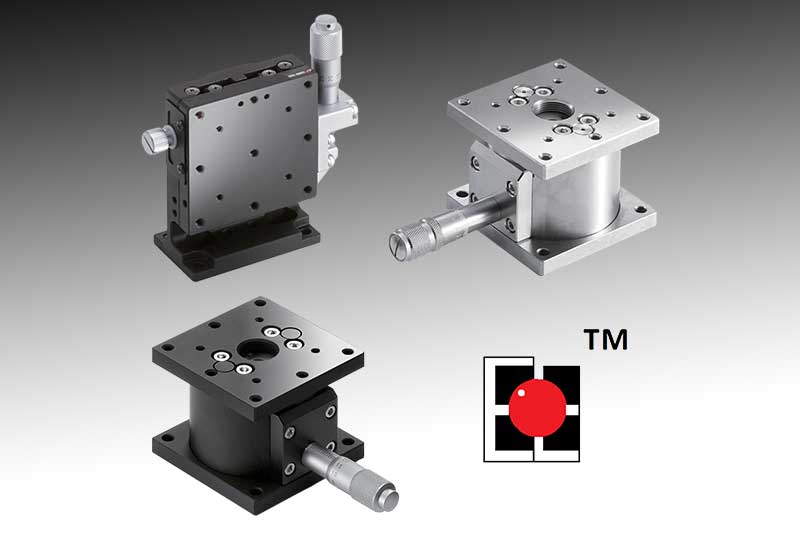

Understanding Our Z-Axis (vertical travel) Stage Offering

OptoSigma® offers three main types of z-axis, vertical-travel stages, each providing different orientations of its mounting surfaces. Z stages have two mounting surfaces: one that is movable and one fixed. The movable surface provides mounting for the object that needs to be aligned or positioned. The fixed surface (or base) mounts to a work surface like a breadboard or optical table.

Each of these surfaces are oriented either horizontally or vertically and, likewise, our stages are grouped into one of three categories shown below:

- Horizontal Mounting Surface /Horizontal Base

- Vertical Mounting Surface /Horizontal Base (part number suffix: “L”)

- Vertical Mounting Surface /Vertical Base (part number suffix: “Z”)

Use this selection guide to identify the z-axis stage that best suits your application need.

|

TYPE |

Vertical Travel (Z-Axis) Stages Options

|

Horizontal Mounting Surface/ Horizontal Base |

Vertical Mounting Surface/ Horizontal Base |

Vertical Mounting Surface/ Vertical Base |

|

|

Main Advantage à |

Highest Load Capacity |

Smallest Foot Print |

Slimmest Vertical Profile |

|

BEARING / MATERIAL |

Precision (EX)c™ Bearing, Hardened Black and Stainless Steel Stages

|

TSD-L Series TSDS-3L Series2 (V6) |

TSD-SZ Series TSD-LONG-SZ Series |

|

|

Crossed Roller, Aluminum Stages

|

− |

TAM-3L Series

|

− |

|

|

Ball Bearing, Aluminum Stages |

− |

TADC-L Series |

TADC-SZ Series |

|

|

Dove Tail, Brass and Aluminum Stages |

TASB-3 Series TAR-3D |

TAR-L TARW-L |

− |

|

|

Linear Bearing, Aluminum Stages

|

− |

LSV Series |

− |

- TSD-UD stages are configured to be mounted upside down

- TSDS series stages are made from stainless steel and prepared for use in 1E-6 Torr vacuum environments.