In stock

SKU

PDM-ACT

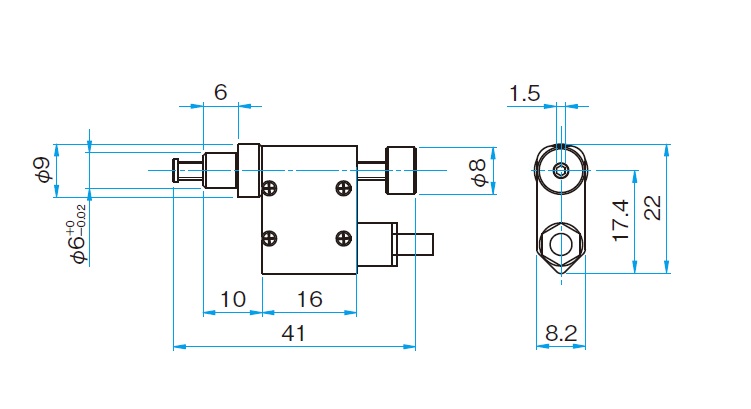

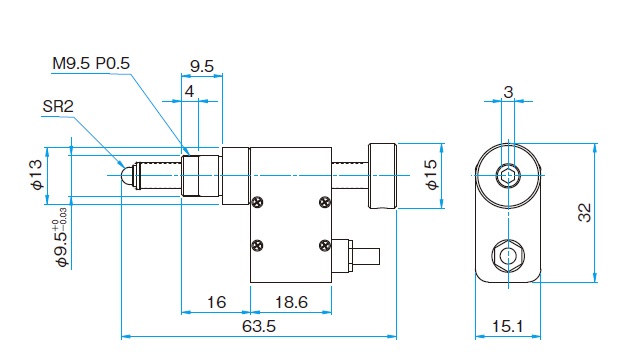

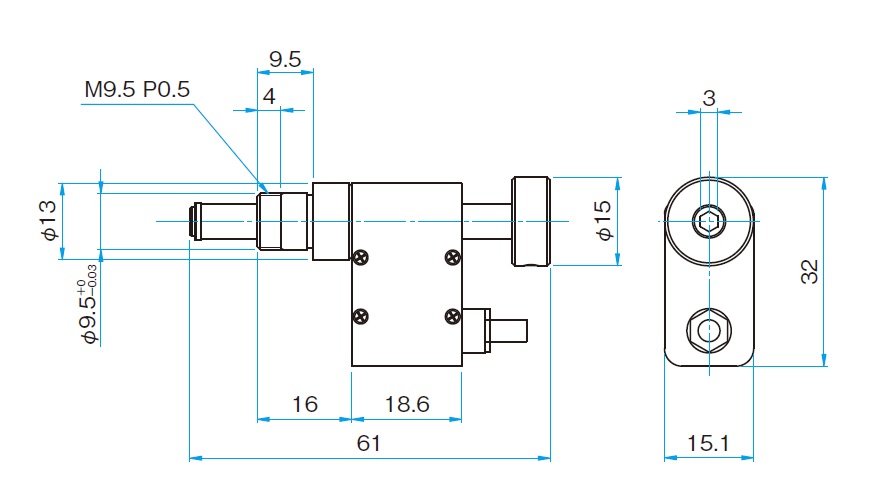

Our piezomotor actuators are compact and provide extremely high-resolution incremental movement, as low as 30nm. One of the key benefits of piezomotor actuation is that the static friction, which is in effect when the piezomotor is not operating, also acts like a locking mechanism. Our PDM peizomotor actuators are available in two travel ranges, 13- and 6.5-mm, and have industry-standard 9.5-mm and 6-mm diameter mounting interfaces allowing them to be drop-in replecements for standard micrometers. They also have either ball-tip or flat-tip options. Another convenient feature of these actuators is that the electrical cable (which is included) is removable from the actuator. Please note that these actuators do not have internal feedback and therefore are open-loop. Vacuum-compatible versions are also available. If your application needs different specifications we can customize our piezomotor actuators to your unique requirements.

Customize product

Filters

Enabled filters :

Remove all filters

| Name |

Travel

|

Delivery | Price | Add to cart | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

details

PDM-6.5ACTR

|

0 - 6.5mm |

in stock

|

€792.10

|

|

|||||||||||||||||||||||

|

details

PDM-6.5ACT

|

0 - 6.5mm |

1 week

|

€792.10

|

|

|

||||||||||||||||||||||

|

details

PDM-13ACTR

|

0 - 13mm |

in stock

|

€693.00

|

|

|||||||||||||||||||||||

|

details

PDM-13ACT

|

0 - 13mm |

6-12 weeks

|

€693.00

|

|

|

You must be logged in to ask questions

The motion of these actuators relies on the structured, high-speed "vibration" of a piezo stack along with the force difference between the friction of a moving object vs. the friction of a non-moving object. Recall that friction on a non-moving object is higher than moving friction. In the motion process, the piezo is expanded slowly, enabling higher static friction, and this makes the screw rotate in a direction. Then, the piezo is retracted very quickly, for lower static friction such that the screw does not rotate. Applying this process repeatedly at a high rate causes the actuator screw to rotate continuously in a particular direction. Simply reversing the order of the fast and slow piezo expansion/retraction reverses the direction of rotation, allowing the screw to move in the opposite direction.