Motorized Linear Stages

-

Low Cost Linear Stages (1 Axis)

-

Compact Linear Stages (1 and 2 axis)

-

Standard Linear Stages (1, 2 and 3 axis)

-

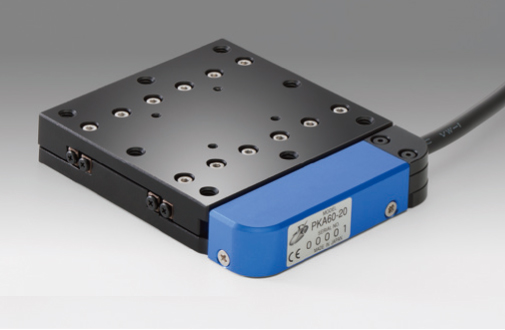

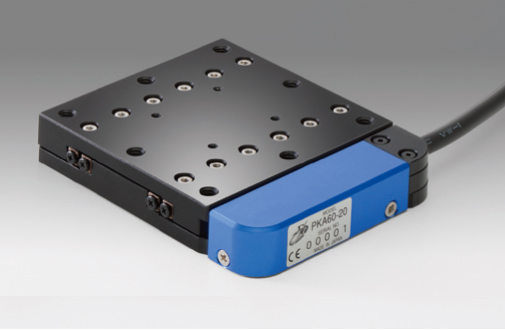

Built-In Controller Linear Stages

-

High Load Linear Stages (up to 40kg, 1, 2 and 3 axis)

-

Closed Feedback Loop Linear Stages (1 Axis)

-

AC Servo Motor Motorized Stages

-

Vertical Travel Horizontal Platform Motor Stages

-

Silent Ultrasonic Linear Stages

-

Miniature Linear Stage (1 axis)

Selection Guide for Linear Motorized Stages

Groups |

Description |

Travel Ranges |

Platform Sizes |

Load Capacity |

Mounting Threads |

Max. Speed |

Repeatability |

Minimum Incremental Motion |

Axis Options |

|---|---|---|---|---|---|---|---|---|---|

Low-Cost Stages |

HPS motorized stages, with ball screws and extended contact bearings offer mid to upper level performance at a low price. |

20, 50, 60 mm |

|

5 – 10kg |

Metric: M4 |

10mm/sec |

±1μm |

0.1μm |

|

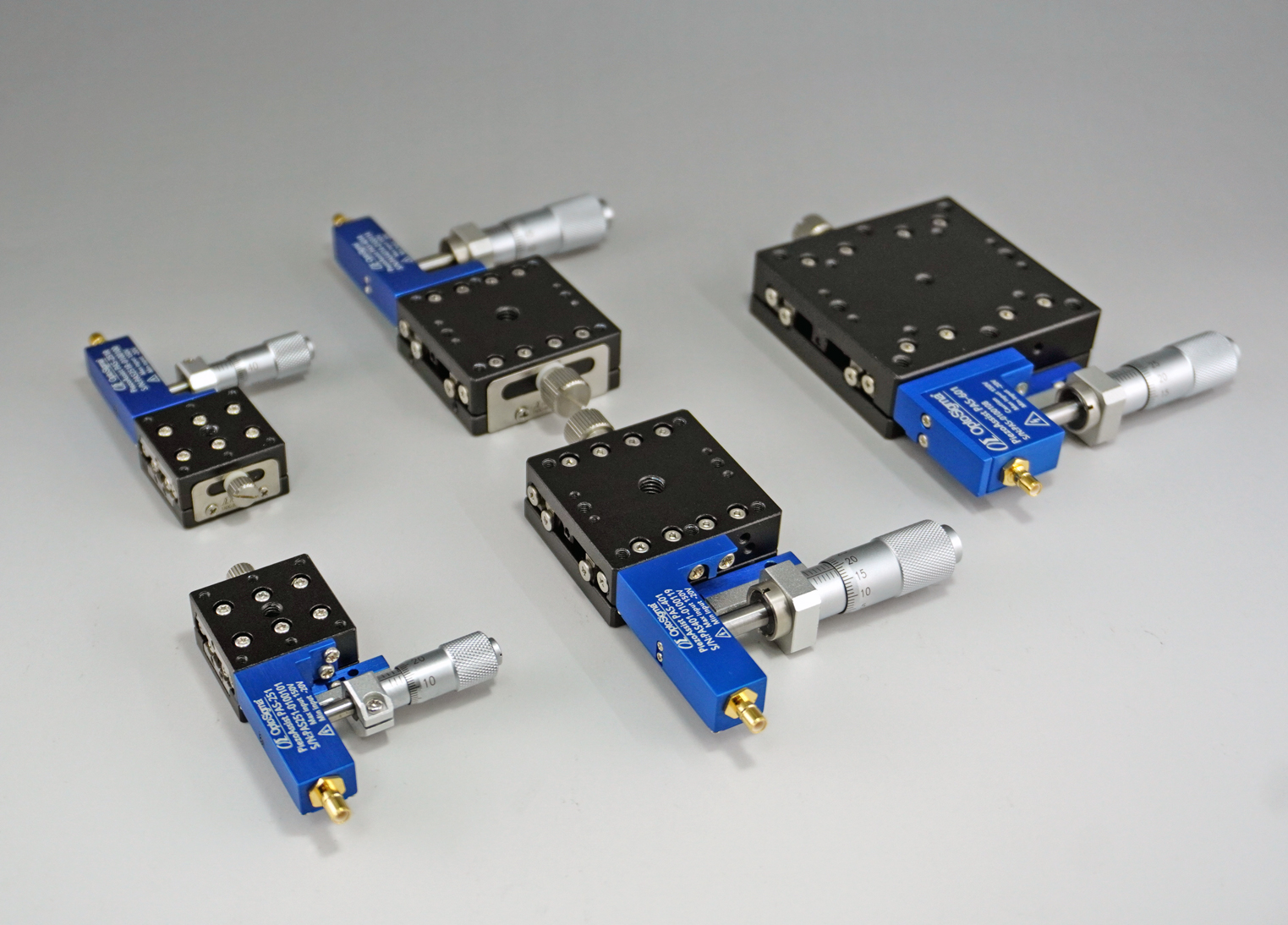

Compact Stages |

TAMM motorized crossed roller stages combine compactness, low-profile, and high durability. They feature anti-creep crossed roller bearings, special nut-shape ball screw, and black anodized aluminum body. |

10, 15, 50, 100mm |

|

3 – 10kg |

Metric: M4 |

10mm/sec |

±1μm |

0.1-0.2μm |

|

Standard Stages |

OSMS standard stepping motor driven stages have the most SKU options of all our stages. They are ideal for positioning of measuring instruments or inspection tools from which high stiffness and high precision are required. |

35, 50, 85, 100, 200, 300, 500mm |

|

3-20kg |

Metric: M4, M6

|

25-40mm/sec |

±±1.5 - 3μm |

0.2-0.4μm |

|

High Load Stages |

HST stages are fitted with precision ball screws and precision crossed roller. The combination of HST Series and 3 axis Stage Controllers HSC-103 can perform low-noise and low-vibration operation, compared with conventional products. Steel body offers excellent stiffness and high load capacity. |

50, 100, 200mm |

|

40kg |

Metric: M4, M6 |

10-20mm/sec |

±1μm |

0.1μm |

|

Closed-Loop Feedback Stages |

OSMS(CS) closed loop motorized stages have optical scales making them a highly accurate and reliable system. The compact scale is built in to keep the envelope dimensions the same as that of the equivalent open loop OSMS series. |

35, 85, 100, 200, 300, 500mm |

|

3-20kg |

Metric: M4, M6

|

25-100mm/sec |

±1 - 1.5μm |

0.2-0.4μm |

|

AC Servo Motor Stages |

SGMV High accuracy / high stiffness stages are driven by AC servo motors. AC motors incorporate encoders for providing feedback and closed-loop control. These motors can be positioned to high accuracy. |

35, 85, 100, 200mm |

|

8-13kg |

Metric: M4, M6 |

35mm/sec |

±2μm - 3μm |

2μm |

|

Vertical Travel Flat Stages |

OSMS Z axis stages offer high stiffness and high precision. The mounting platform is oriented parallel to the base and is perpendicular to the direction of travel to minimize footprint. |

5, 10, 20mm |

|

2-15kg |

Metric: M3, M4 |

1-4mm/sec |

±2.5μm |

0.05-0.10μm |

|

Silent Ultrasonic Linear Stages |

PKA translation stages provide silent, high resolution position. While the drive source is a small ultrasonic motor, high load capacity of 2gk is ensured. |

15, 20mm |

|

2kg |

Metric: M3, M4 |

0.5mm/sec |

3.5-16mm |

2μm |

|

Fine Piezo Stages |

SFS piezo stages offer high precision and resolution positioning by utilizing full closed loop control with digital frequency based sensors. Using piezo element actuators, minimum incremental motion as small as 1nm. |

266, 355, 532nm |

|

7-15kg |

Metric: M3, M4 |

NA |

±0.05 μm |

0.001-0.050μm |

|

Miniature Linear Stage |

These objectives are designed with compensation for cover glass-thickness aberrations, making it possible to realize ideal beam spot size and quality while processing thorough a cover glass. These objective lenses can be used for laser repair processing for LCD or OLED modules. |

10mm |

|

2kg |

Metric: M2 |

10mm/sec |

±1.5 μm |

2μm |

|

Vacuum Compatible Stages |

Motorized VSGSP stages are modified for use in high vacuum. These linear stages have available travel between 35 − 200mm and have a similar footprint to the SGSP series. |

35, 85, 200mm |

|

39-59kg |

Metric: M3, M4 |

10-20mm/sec |

±2.5 - 5μm |

0.2μm |

|

Piezo-Assist Stages |

TADC-SPA stages allow fine adjustment of 20nm or less by having a piezo assist mechanism integrated into the manual stage. They are ideal for manual stage units and systems that require high resolution position adjustment. |

6, 13mm |

|

4-5kg |

Metric: M3, M4 |

NA |

NA |

0.020μm |

*The indicated millimeter-to-inch diameter conversion values are rounded